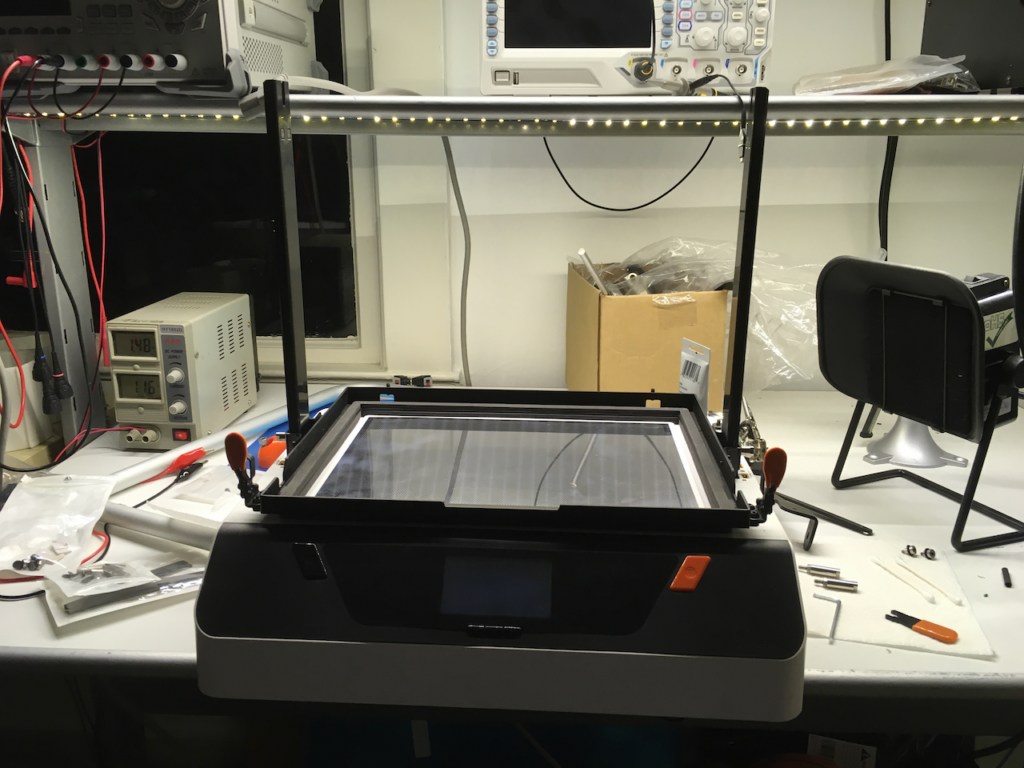

A friend of mine bought a desktop thermoforming machine and let me borrow it.

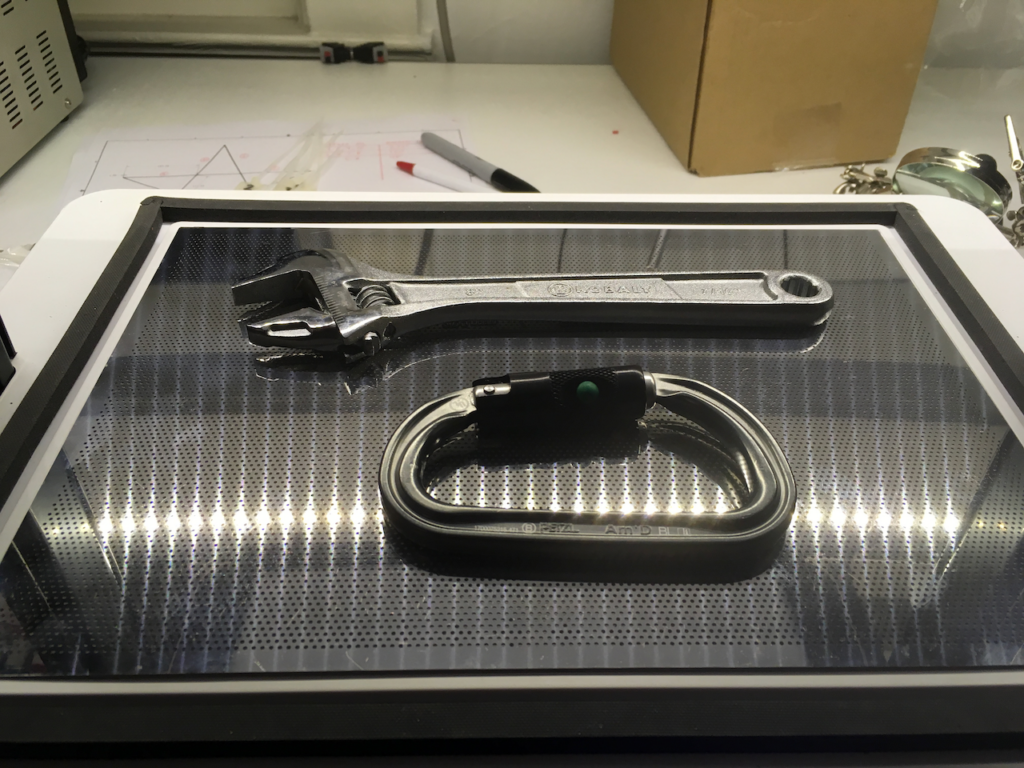

I immediately grabbed a couple interesting objects around the house to pull a test form. The first sheet actually went surprisingly well, not a bad little machine!

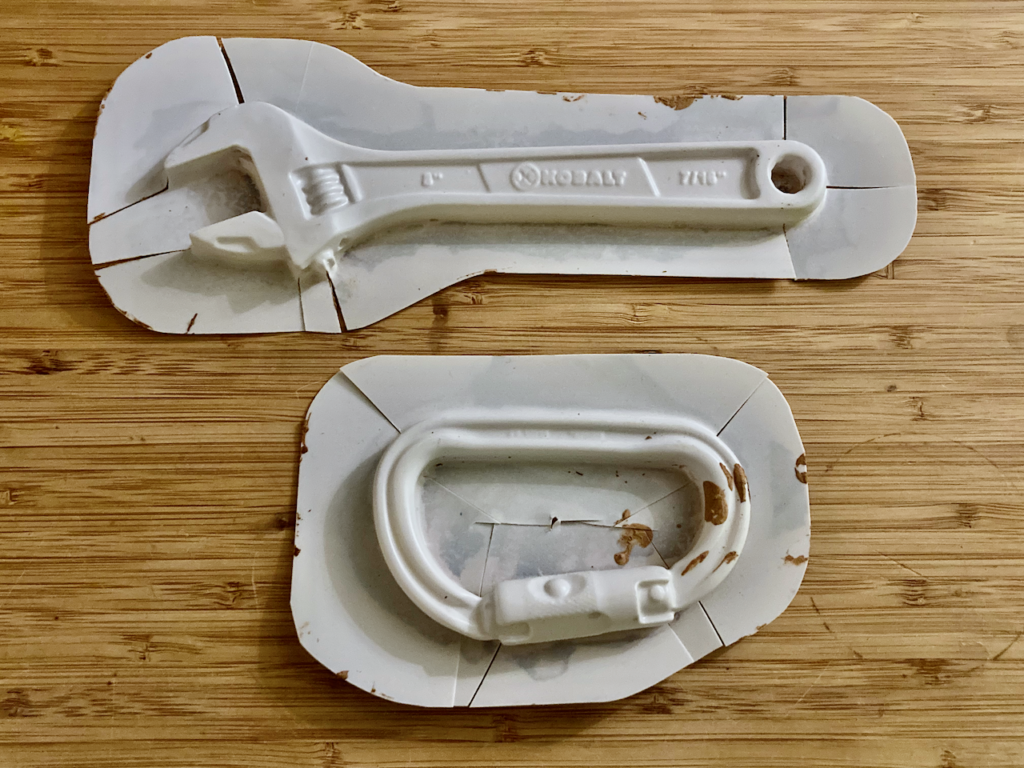

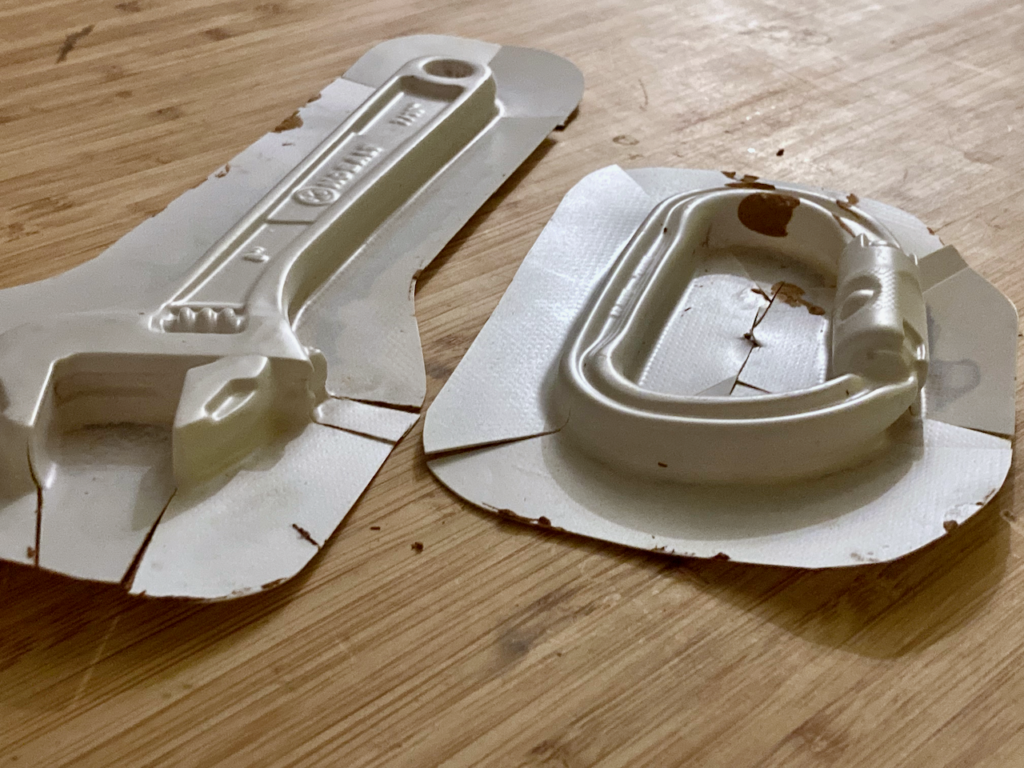

In fact, the first pull worked so well that it actually managed to exceed my expectations and pull material into the undercuts of the parts — rendering them quite securely stuck to the formed sheet. Now one of the key advantages of the thermoforming process is cheap and easy tool (mold) creation. Undercut areas are generally not well suited to the process, as this rapidly increases the tool complexity and cost. In this case, I was able to cheat by cutting the sheet to form relief areas. If one were actually trying to make proper molds for these objects you would use a casting process, which is far more compatible with complex undercut geometry.

Now that the relief slits were cut in the sheet, I was finally able to extract the objects and was left with a mediocre but usable negative casting mold. Naturally, an attempt had to be made to try casting some chocolate. I had never casted chocolate, and it turns out there is actually a lot going on when it comes to tempering chocolate. After taping up the molds and doing my best to prepare the chocolate, I poured a first set of parts!